Let’s break down the concepts of “cast iron water heater” and “grate” in an industrial context, especially relevant to a place like Hanoi, Hung Yen, Vietnam. It’s important to clarify that “cast iron water heater” usually refers to a boiler made of cast iron sections, primarily for hydronic (hot water) heating or low-pressure steam, rather than a domestic water heater.

Cast Iron Water Heater (Boiler)

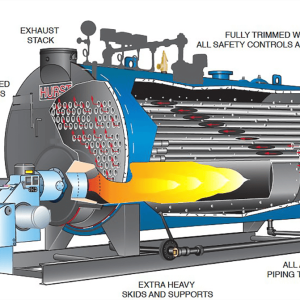

A cast iron water heater in an industrial or large commercial context is typically a cast iron sectional boiler. These boilers are assembled from individual cast iron sections that are bolted or connected together to form a larger heat exchanger. They can be used for either hot water heating systems or low-pressure steam applications.

How it Works:

- Sectional Design: Unlike fire-tube or water-tube boilers which use continuous tubes, cast iron boilers consist of multiple cast iron sections. Water flows through internal passages within these sections.

- Combustion Chamber: A burner (fueled by gas or oil) fires into the combustion chamber formed by these sections, or a solid fuel combustion chamber is located beneath them.

- Heat Transfer: Hot gases from combustion pass over the external surfaces of the cast iron sections. Heat is transferred through the cast iron walls to the water contained within the sections.

- Circulation: The heated water (or steam) then circulates out to the heating system (e.g., radiators, heat exchangers), and cooler water returns to the boiler to be reheated, completing the cycle.

Advantages of Cast Iron Boilers:

- Durability and Longevity: Cast iron is highly resistant to corrosion from condensate, and sections are thick and robust. Many cast iron boilers can last for decades, often exceeding the lifespan of steel boilers if properly maintained.

- Thermal Inertia (Heat Retention): Cast iron has high thermal mass. It takes longer to heat up, but once hot, it retains heat exceptionally well. This can lead to more stable heating and potentially fewer burner cycles, especially in systems with consistent demand.

- Modular Design: The sectional nature allows for easier transport and assembly in spaces with limited access. If one section fails, it can theoretically be replaced without replacing the entire boiler (though full replacement is often more cost-effective for very old units).

- Resistance to Thermal Shock: While cast iron can crack from severe thermal shock (e.g., introducing very cold water into a very hot, low-water boiler), they are generally more forgiving of temperature fluctuations than some other materials.

- Good for Older Systems: Often a good replacement choice for existing hydronic systems that were originally designed with cast iron components (like cast iron radiators), which also benefit from slow, radiant heat.

Disadvantages of Cast Iron Boilers:

- Weight: Cast iron is very heavy, making installation and transport more challenging and costly. Requires strong foundations.

- Slow Heat-Up Time: Due to their high thermal mass, they take longer to reach operating temperature compared to lighter steel boilers.

- Lower Operating Pressure/Temperature Limits: Cast iron boilers are typically limited to low-pressure steam (e.g., up to 15 psi) or hot water applications (e.g., up to 160 psi and 250°F / 121°C). They are not suitable for high-pressure steam industrial processes.

- Susceptibility to Cracking: While durable, cast iron is brittle. Improper installation, severe thermal shock, or prolonged low-return water temperatures (leading to condensation and corrosion) can cause sections to crack, necessitating costly repairs or replacement.

- Cleaning: Internal passages can be harder to clean compared to fire-tube or water-tube designs, which can lead to scale buildup if water treatment is not adequate.

- Less Common for Large Industrial Use: For very large industrial steam or high-temperature hot water demands, steel fire-tube or water-tube boilers are generally preferred due to higher pressure capabilities and more compact designs for high output.

Applications in Vietnam:

In Vietnam, cast iron sectional boilers are primarily found in:

- Commercial Buildings: Hotels, offices, schools, hospitals for space heating and domestic hot water.

- Smaller Industrial Facilities: For process heating where low-pressure steam or hot water is sufficient, such as small laundries, food processing units, or textile operations, especially if they value longevity and stable heat.

- Residential Complexes: Though less common for individual homes now, older apartment buildings might still use them.

Grate

A grate in the context of industrial heating refers to the platform or bed where solid fuels are burned in a boiler’s combustion chamber. It’s a critical component for solid fuel combustion systems.

Types of Grates (relevant to industrial boilers):

- Stationary Grate (Fixed Grate):

- Description: As discussed previously, this is a non-moving bed of cast iron or steel bars (or sometimes refractory material) where fuel is manually or mechanically fed. Air is supplied from below through perforations or gaps in the grate.

- Application: Commonly used in smaller to medium-sized industrial boilers burning various solid fuels like coal, wood chips, rice husks, coffee husks, sawdust, bagasse, etc. Very common in Vietnam, especially in industries with readily available biomass waste (e.g., rice mills in Mekong Delta, wood processing factories near Hanoi).

- Advantages: Simple design, robust, can handle a wide range of fuel sizes and moisture content, relatively low cost.

- Disadvantages: Requires more manual labor for feeding and ash removal (unless partially automated), generally lower combustion efficiency and higher emissions (PM, NOx) compared to more advanced grate types, prone to clinker formation if not managed well.

- Vibrating Grate:

- Description: The grate surface is made of segments that periodically vibrate or oscillate. This motion helps to continuously feed fuel, break up the fuel bed, and discharge ash into an ash pit.

- Application: Used for a wider range of solid fuels than stationary grates, often with varying moisture content. Provides better combustion control and ash removal.

- Advantages: Improved combustion efficiency over stationary grates, reduced manual intervention, better for fuels with moderate ash content.

- Disadvantages: More mechanically complex than stationary grates, higher initial cost.

- Traveling Grate (Chain Grate):

- Description: A continuous conveyor belt-like grate, typically made of interlocking cast iron links. Fuel is fed onto one end and slowly moves across the grate as it burns. Ash is discharged at the other end.

- Application: Common in medium to large coal-fired boilers, and for some biomass applications where continuous, automated feeding and ash removal are desired.

- Advantages: Fully automated fuel feeding and ash removal, good combustion efficiency, suitable for large capacities, more consistent steam output.

- Disadvantages: High initial cost, mechanically complex, less flexible with fuel type compared to some other grates (requires consistent fuel size).

- Reciprocating Grate (Pushing Grate):

- Description: Consists of alternating fixed and moving grate bars that “push” the fuel along the grate, agitating the bed and breaking up clinkers.

- Application: Excellent for fuels with high moisture content and high ash content, or waste-to-energy applications (incinerators) where fuel characteristics can vary widely.

- Advantages: Highly effective fuel agitation, good for diverse and challenging fuels, excellent ash discharge.

- Disadvantages: Most mechanically complex, high initial cost.

Why Cast Iron for Grates?

Cast iron is a preferred material for grate bars in solid fuel boilers due to several key properties:

- High Temperature Resistance: Cast iron can withstand the high temperatures of a combustion bed without significant deformation or melting.

- Wear Resistance: It’s tough and resistant to abrasion from the moving fuel bed and ash.

- Corrosion Resistance: It holds up well against the corrosive elements often present in solid fuel ash (especially sulfur compounds).

- Heat Retention: Helps in maintaining a stable ignition front in the fuel bed.

- Cost-Effectiveness: Relatively economical to cast into complex shapes required for grate bars, compared to high-alloy steels.

In Vietnam, where industries still widely use solid fuels like biomass and coal, understanding the type and maintenance of grates is crucial for efficient and compliant boiler operation. The choice of grate depends heavily on the fuel available, the scale of the boiler, and the budget for initial investment versus operational complexity and emissions control.

Đặt câu hỏi