Let’s delve into oil-fired, LNG, and CNG boilers, considering the local context.

1. Oil-Fired Boiler

Fuel: Various grades of fuel oil (e.g., FO, DO – Diesel Oil, sometimes heavy fuel oil).

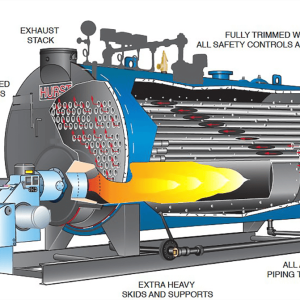

Mechanism: As explained previously, oil is stored in tanks, pumped to the burner, atomized, and ignited to heat water/thermal oil for steam generation.

Key Considerations in Vietnam:

- Availability: Fuel oil is widely available across Vietnam, often distributed by Petrolimex and other companies. This offers flexibility, especially for locations not connected to a gas grid.

- Storage: Requires significant on-site storage, which has land footprint implications and strict safety regulations (fire prevention, spill containment).

- Environmental Impact: This is a major drawback. Oil combustion, especially heavy fuel oil, produces higher emissions of:

- Particulate Matter (PM): Soot and fine dust, contributing to air pollution.

- Sulfur Oxides (SOx): Due to sulfur content in the fuel, leading to acid rain and respiratory issues. Vietnam has been tightening regulations on sulfur content in fuels.

- Nitrogen Oxides (NOx): Formed at high combustion temperatures.

- Carbon Dioxide (CO2): Higher carbon footprint per unit of energy compared to natural gas.

- Vietnamese Regulations (Current and Future): Vietnam’s Law on Environmental Protection (2020) and subsequent circulars (like Circular No. 45/2024/TT-BTNMT for industrial emissions, effective early 2025) are tightening environmental standards. This puts pressure on facilities using oil, often requiring advanced flue gas treatment systems (e.g., scrubbers for SOx) which add to CAPEX and OPEX.

- Maintenance: More frequent cleaning of heat exchange surfaces is typically needed due to soot buildup.

- Price Volatility: Global oil prices are subject to significant geopolitical and supply/demand fluctuations, directly impacting operational costs. Recent reports (July 2025) indicate some oil price volatility.

- Efficiency: Modern oil boilers can be highly efficient, but older units might be less so.

2. Gas LNG Boiler (Liquefied Natural Gas)

Fuel: Natural gas, which has been cooled to -162°C (-260°F) to turn it into a liquid, reducing its volume by about 600 times. Primarily methane (CH4).

Mechanism: LNG is stored in cryogenic tanks at the industrial site. Before use, it passes through a regasification unit (vaporizer) that converts it back into gaseous natural gas. This gas is then fed to the boiler burner for combustion.

Key Considerations in Vietnam:

- Environmental Benefits: This is its strongest advantage. LNG is considered the cleanest-burning fossil fuel.

- Significantly lower CO2 emissions (up to 25% less than oil).

- Negligible SOx emissions (due to purification during liquefaction).

- Lower NOx and particulate matter emissions compared to oil.

- Aligns well with Vietnam’s commitment to net-zero emissions by 2050 and stricter environmental regulations (QCVN on industrial emissions).

- Availability: Vietnam is increasingly investing in LNG import infrastructure. The Cai Mep LNG terminal is operational, and others are planned. This makes LNG a growing option, especially for industrial zones not directly connected to domestic gas pipelines. LNG is transported by specialized cryogenic trucks from import terminals to industrial sites.

- Storage: Requires specialized cryogenic storage tanks on-site. While these are more expensive than oil tanks, they can store a larger energy equivalent in a smaller footprint compared to CNG, and are much cleaner.

- Safety: While natural gas is flammable, LNG is stored at very low temperatures and has a high auto-ignition temperature and narrow flammability range, making spontaneous ignition unlikely. It also disperses quickly if leaked (lighter than air after regasification).

- Operational Costs: Generally competitive with fuel oil, often more stable. While the liquefaction and regasification process adds cost, the efficiency and reduced maintenance can offset this.

- Infrastructure: Requires investment in LNG storage and regasification units at the plant.

3. Gas CNG Boiler (Compressed Natural Gas)

Fuel: Natural gas compressed to high pressures (typically 200-250 bar) at ambient temperature. Primarily methane (CH4).

Mechanism: CNG is transported in high-pressure cylinders or trailers. At the industrial site, the gas is typically depressurized using pressure regulating stations before being fed to the boiler burner.

Key Considerations in Vietnam:

- Environmental Benefits: Similar to LNG, CNG is a very clean-burning fuel, offering significant reductions in CO2, NOx, SOx, and particulate matter compared to fuel oil.

- Availability: CNG is sourced from existing natural gas pipelines (if available) and compressed, or from dedicated CNG compression facilities. Its availability is tied to the natural gas distribution network. For locations further from pipelines, it’s transported by truck in specialized high-pressure containers.

- Storage: Requires high-pressure storage cylinders or cascades on-site. These take up more space for the same energy content than LNG, and are limited by the pressure capacity.

- Capital Cost: Generally, CNG fueling stations and storage facilities are less expensive to build than full LNG terminals, but more expensive than basic oil storage.

- Transportation: The lower energy density of CNG (compared to LNG) means more frequent deliveries or larger delivery vehicles are needed for the same energy supply. This limits its economic viability for very large energy consumers far from a compression station.

- Safety: High-pressure gas requires robust safety measures, but like LNG, natural gas disperses quickly if leaked.

- Operational Cost: Pricing is generally linked to natural gas prices and compression/transportation costs.

Comparison Summary (in Vietnam Context – Hanoi/Hung Yen)

Đặt câu hỏi