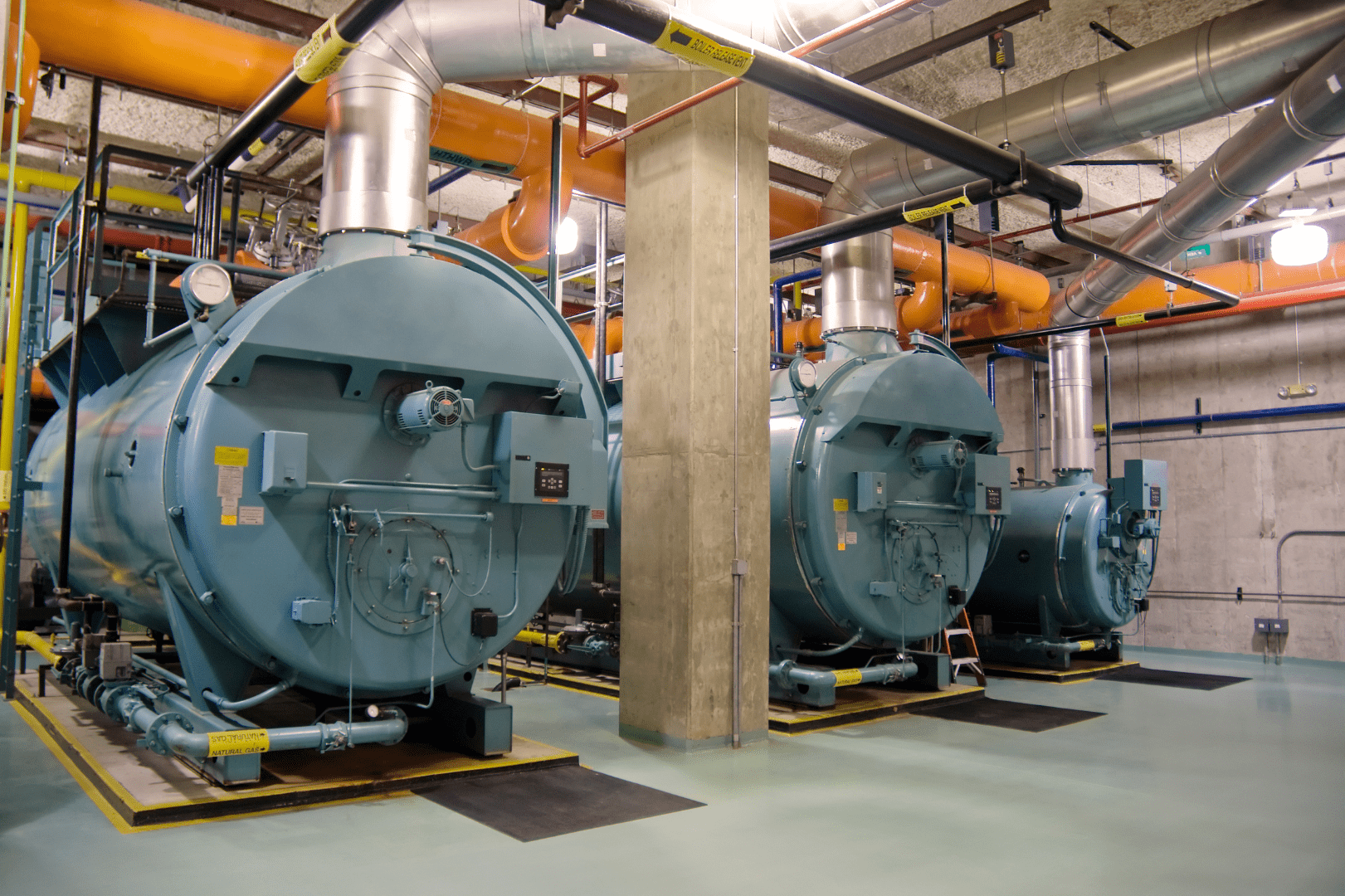

Industrial boilers or industrial boilers are widely used in industrial parks, workshops, and factories. Join GDP Group to find out what an industrial boiler is and the popular types of industrial boilers below.

What is an industrial boiler?

Industrial boilers are also known as Steam Boilers (English: Steam Boiler). Normally, the raw materials used by industrial boiler systems are coal, firewood, rice husks, oil, gas, etc. Used to boil water to create hot steam at high temperature and high pressure. Depending on the industry, different amounts of heat energy will be consumed.

You can actively adjust the temperature and pressure on this boiler system. Depending on the factory’s needs, adjust accordingly. Heat-resistant pipes also play an important role in the transportation process.

The birth of industrial boiler systems is an important step forward in the manufacturing industry. The boiler system operates to create clean energy; but does not affect fire or oil prohibited areas.

Structure of industrial boiler

- Feeding system: equipped with automatic or semi-automatic operation. Includes equipment such as loaders, scoops, material hoppers, buckets, conveyors, and screw conveyors. Arranged for interlocking control, self-dosing and self-feeding of the boiler. The feeding system is also equipped with a weight scale to determine the amount of fuel consumed.

- Combustion chamber – Furnace body: Designed to burn fuel as completely as possible. Best heat absorption for steam generation. Includes equipment such as: combustion chamber, burner, heat radiation absorption tube beam, steam generation tube beam.

- Heat recovery unit (water heater, air dryer): To utilize the heat from exhaust smoke, increase boiler efficiency and reduce the temperature of exhaust smoke into the environment.

- Dust filtration system: You can choose some of the following dust filtration devices: cloth bag dust filter, electrostatic dust filter, multi-level dust filter cyclone, wet dust filter tower, ash settling tank. To treat ash from the fuel combustion process of the boiler. The purpose is for the smoke released from the chimney to ensure environmental standards prescribed by the state.

- Exhaust fan and chimney: Exhaust smoke after heat has been utilized. Dust filtering through many levels will be pushed up the chimney by the exhaust fan and discharged into the environment.

Popular types of industrial boilers

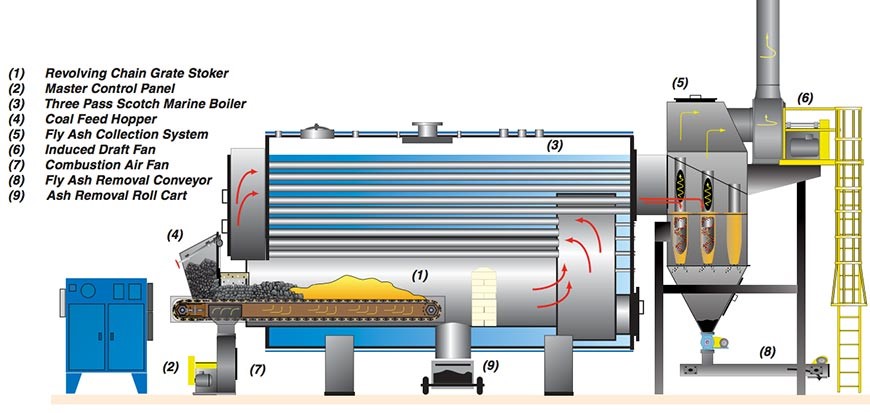

Chain grate boiler

Chain grate boiler (chain grate coal fired boiler) is a type of boiler with medium or large capacity, quite commonly used in industries. There are two types of chain grate boilers: static grate and dynamic grate. Static recording is a form of recording that lies still, while dynamic recording moves like a conveyor belt. Fuel is supplied and burned on the grate, forming slag which is released on the grate.

Principle of operation

Chain grate boilers use coal or organic solid fuel to feed the grate with a pre-adjusted thickness. They move together and burn into the fire chamber. Here, the fuel receives radiant heat from the furnace, walls, and flames. The coke burns and the substance evaporates to form ash, which is then scraped and discharged. The thickness of the fuel layer on the recording surface is selected appropriately for each type of fuel.

Characteristic:

- Coal supply and slag disposal are completely automatic; operates with stable temperature and pressure;

- Can burn many different types of fuel;

- Simple operation and durable.

- Designed for easy maintenance.

- Burn coal and raw materials in many steam consumption modes.

Rice husk boiler

Rice husk boilers (boilers using rice husks) are one of the very popular types of boilers. A special feature of the boiler is the use of cheap fuel, rice husk. Rice husks from the boat are sucked into the rice husk warehouse, then brought to the mouth of the container and placed on the hopper at the top of the furnace. Rice husk will be heated and then sprayed into the combustion chamber using a fan. Rice husk feeding speed is adjusted by loading vis. When burning rice husks are suspended, they will fall and continue to burn on the burning surface. Rice husk ash is brought to the end of the grate and taken out by ash conveyor.

Principle of operation

From the rice husk storage, put the rice husk into the storage hopper placed at the top of the boiler. Rice husk is heated and sprayed into the combustion chamber by the boiler blower. Burned rice husks are suspended inside and fall onto the recording surface, then continue to burn on the recording surface. After burning out, the ash remains and is brought to the bottom of the burner to be taken out. The speed of loading rice husk inside is adjusted via the loading vis.

Characteristic:

- Easily handle the problem so that the amount of exhaust smoke meets environmental standards in Vietnam.

- The amount of rice husk consumed is low, about 200kg of rice husk/1 ton of steam.

- Save costs on steam production.

Industrial combination boiler, multi-purpose boiler

Combination boilers and multi-purpose boilers are boilers that operate based on a combination including: fire tube in the convection section, water tube in the radiation chamber and combustion chamber.

The advantage of a combination boiler is that its boiler efficiency is higher and more stable than other types of boilers. Also because the boiler design has an additional large water tank. Combination boilers are currently also one of the most widely used and popular types of industrial boilers.

Boiler burning gas, DO oil and biomass

Today’s gas, DO, and biomass-burning boilers are extremely modernly designed with a fully automatic operating system. The operating process therefore operates smoothly and stably, with low prices and thoughtful maintenance and care. It is for this reason that gas, DO oil and diomass boilers are widely used today.

Advantage:

- High oil-fired boiler efficiency: >90%

- The mechanism works completely automatically.

- Smooth operating process

- Compact design, takes up little space.

- Steam level is fast and stable.

- Easy inspection and maintenance.

- No dust or smoke.

Thermal oil boiler

Thermal oil boilers use oil or gas to operate. This is a type of boiler that meets the needs of use in the process of drying, dyeing, running machines, cooking, processing agricultural products, weaving, etc. in factories and enterprises. Thermal oil boiler is designed as a spiral tube, placed horizontally. The heating tubes will be continuously twisted with springs with different numbers of connections depending on each heat capacity.

- The burning mode is in layers, so the burning speed is stable and has large thermal inertia, thereby providing heat at a stable level.

- High capacity, long lifespan thanks to recording durability. Fires in layers so smoke does not carry much dust or ash. This reduces the possibility of abrasion of the heating tube.

- Capable of burning together or burning each type of fuel separately.

- Heating furnace smoke does not carry too much ash, so ash disposal is simple.

- Operating costs are low, operations are largely automatic.

Application of industrial boiler

Industrial boilers are industrial equipment widely used in factories; Enterprises, thanks to the ability to generate and conduct heat (steam), are the main source of heat for equipment; Machines that require heat:

- Industrial boilers are widely used in a number of factories such as: Confectionery production; animal feed factory;…

- In addition, the boiler is also used to cook and pasteurize foods such as fish sauce and soy sauce; vegetable oil, soft drinks…

- Boilers play a sterilizing role in the processes of a number of industries such as healthcare, environmental treatment, printing, chemicals, textiles, and rubber production; plastics and plasticizers,…

- Also in industry; Boilers are used as a heat source to operate some mechanical equipment.

GDP Group specializes in providing quality industrial boilers

Each type of boiler uses different fuel to operate and has different capacities, so the price will be different. The price of industrial boilers ranges from 40 million VND for wood-burning and rice-husk boilers with a capacity of 50 kg/h to several hundred million for boilers with larger capacities. For details about each type of industrial boiler, please contact GDP Group immediately for detailed quote advice:

CÔNG TY TNHH CƠ NHIỆT XANH GDP

Nhà máy: CCN Mả Ông, P. Đình Bảng, TP. Từ Sơn, tỉnh Bắc Ninh

Số điện thoại: 0983 14 6666

Email : dungbk1102@gmail.com

Website : gdpgroup.vn