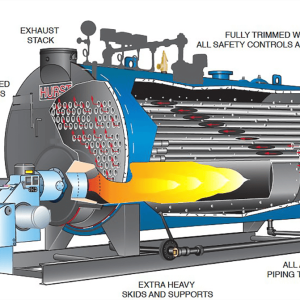

Chain grate boiler is a device that uses heat from burned fuel (coal, firewood, rice husk, biomass, …) to heat water into steam to serve production or electricity generation needs. Depending on the purpose of use, it creates a steam source with suitable temperature and pressure to meet the needs of use. Boilers can be divided into 3 types: energy boilers, industrial boilers, and civil boilers.

Khi quá trình cháy diễn ra, nhiệt lượng toả sẽ truyền nhiệt cho các dàn ống sinh hơi đặt xung quanh buồng đốt. Nước trong các ống của dàn ống sinh hơi được đun nóng đến sôi và sinh hơi. Hỗn hợp hơi nước sinh ra được đưa lên tập trung ở bao hơi. Bao hơi dùng để phân ly hơi ra khỏi hỗn hợp hơi nước. Phần nước chưa bốc hơi có trong bao hơi được đưa trở lại các dàn ống sinh hơi qua hệ thống ống xuống đặt ngoài vách ướt (để không hấp thụ nhiệt). Nước đi trong các ống nước xuống không được đun nóng, có trọng lượng riêng lớn hơn hỗn hợp hơi nước ở trong các dàn ống sinh hơi. Điều đó tạo nên sự chênh lệch trọng lượng cột nước làm cho môi chất chuyển động tuần hoàn tự nhiên trong vòng tuần hoàn kín. Nhưng khi áp suất làm việc của nồi hơi đạt trạng thái cận tới hạn hoặc tới hạn trở lên thì phải sử dụng bơm tuần hoàn để hỗ trợ nước chuyển động qua dàn ống sinh hơi. Hơi ra khỏi bao hơi là hơi bão hòa, nếu cần chất lượng hơi quá nhiệt thì đưa hơi này qua bộ quá nhiệt để gia nhiệt thành hơi quá nhiệt có nhiệt độ cao.

Đặt câu hỏi