GDP Group – professional and reputable manufacturer of Thermal Oil Furnaces in Vietnam.

Thermal oil furnaces, also known as thermal oil furnaces, are industrial equipment that use oil as an intermediate fluid to transfer heat from the combustion source to heat-consuming devices. Instead of using steam as in boilers, thermal oil furnaces use oil that can withstand high temperatures at low pressure, helping to increase efficiency and safety in operation.

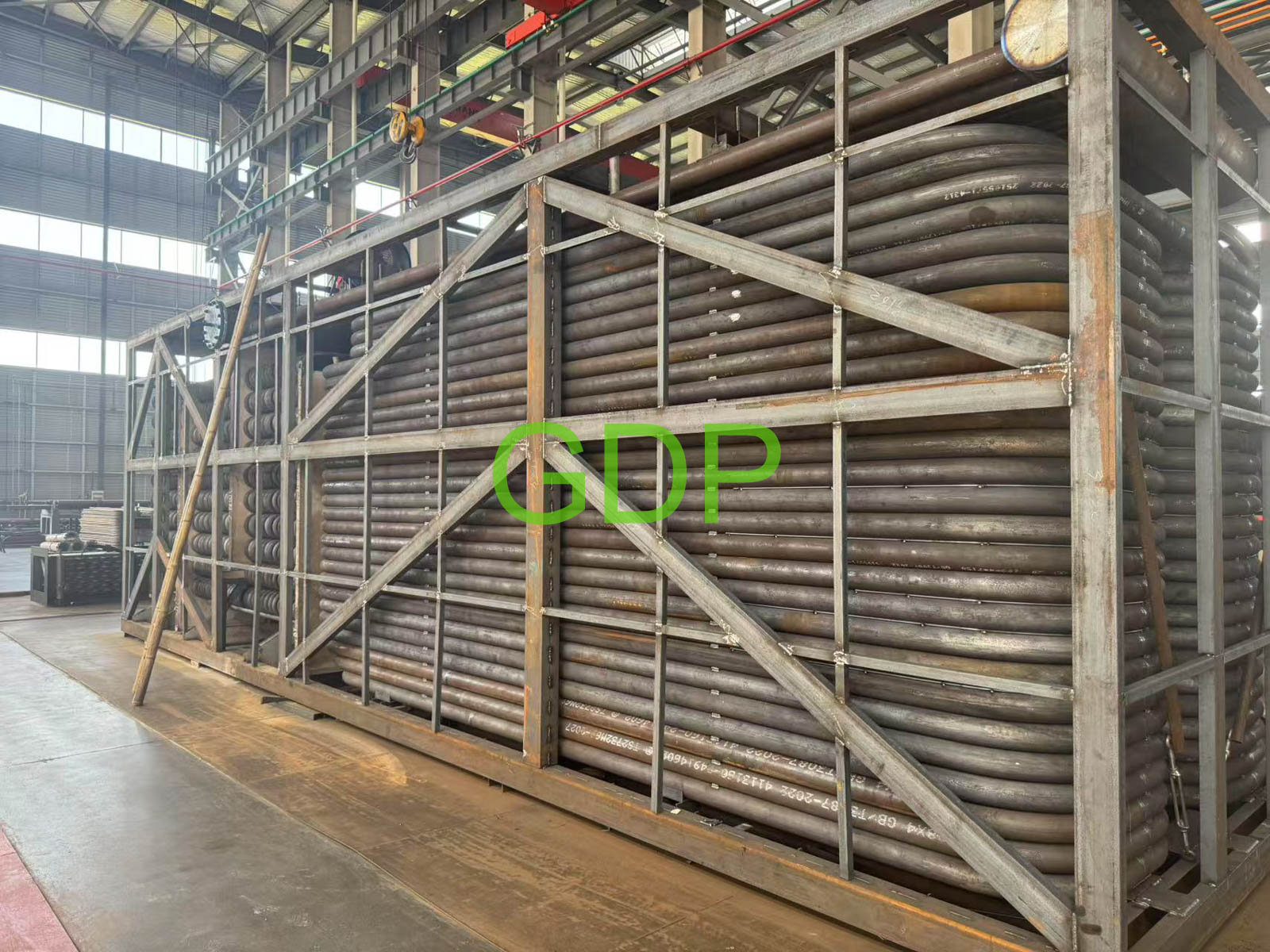

GDP Group – professional and reputable manufacturer of thermal oil furnaces in Vietnam

The thermal oil furnace can be called a thermal oil furnace that uses a fluidized bed combustion chamber to burn fuel, the energy generated from the fuel combustion process will heat the thermal oil, the temperature of the oil after heating can reach up to 400oC. The oil after heating will be sent to heat-using equipment in industrial production. In industry, thermal oil furnaces are only used for indirect heat exchange systems, the oil will pass through heat exchangers, the heat will be reduced and then pumped back to the oil furnace for heating, so the oil will circulate in a closed cycle. The fluidized bed thermal oil furnace can meet the capacity of 80 million cal.

This is a model of a thermal oil boiler system that uses a variety of fuels such as: Coal, Biomass… providing a solution to reduce energy and costs when operating the boiler.

Operating principle:

1. Heat source:

Thermal oil furnace uses fuels such as coal, firewood, oil, or gas to generate heat.

2. Heating oil:

Heat from the combustion source is transferred to the thermal oil, increasing the temperature of the oil to the desired level (usually from 150-400°C).

3. Heat transport:

Hot oil is pumped through the piping system to the equipment, machinery, or production lines that need heat.

4. Heat exchange:

Hot oil releases heat at heat exchange devices, providing heat for the production process.

5. Circulation:

After releasing heat, the oil is returned to the oil furnace to continue the heating process, forming a closed cycle.

Advantages of thermal oil furnace:

High efficiency:

Oil has good heat transfer ability, helping the furnace operate efficiently and save fuel.

Safety:

Operating at lower pressure than boilers, reducing the risk of explosion and high pressure-related incidents.

Thermal stability:

Maintaining stable temperature, meeting the requirements of production processes requiring high precision.

Less corrosion and scale:

Because it does not use water, thermal oil furnaces are less affected by corrosion and scale, helping to increase the life of the equipment.

Cost savings:

Investment, maintenance and operating costs are often lower than those of traditional boilers.

Application:

Thermal oil furnaces are widely used in many industries such as:

- Textile: Drying, dyeing, finishing fabric.

Food: Drying, concentrating, pasteurization.

Chemical: Chemical reaction, distillation, concentrating.

Plastic: Heating, plastic pressing, shaping.

Wood: Wood drying, wood pressing.

Paper: Paper production, paper drying.

Hospital: Drying, steaming, sterilization.

Popular types of thermal oil furnaces:

- Wood, coal, biomass thermal oil furnace: Uses biomass fuel, environmentally friendly.

- Oil and gas thermal oil furnace: Uses fossil fuel.

- Fluidized bed thermal oil furnace: Can burn many types of fuel, high efficiency.

Gdp Group produces high-performance thermal oil furnaces for many industries:

Heating oil furnaces are widely used in industries requiring large, stable heat:

Chemical industry – oil and gas.

Food – beverage.

Plastic – rubber.

Wood – MDF – veneer.

Ceramic tiles – construction materials.

Paint – printing ink – asphalt.