GDP group – a unit that produces and manufactures compressed air tanks. Air tanks are usually made from alloys, anti-corrosion, anti-rust metals used in the manufacture of air tank shells of air compressor systems. Using a compact design, saving space in industrial air compressor systems.

To ensure the safety of equipment operators, compressed air tanks are coated with a layer of electrostatic paint on the outside of the shell, with many different outstanding colors such as: yellow, gray, orange, red, blue …

GDP group – manufacturing and fabrication unit of compressed air tanks

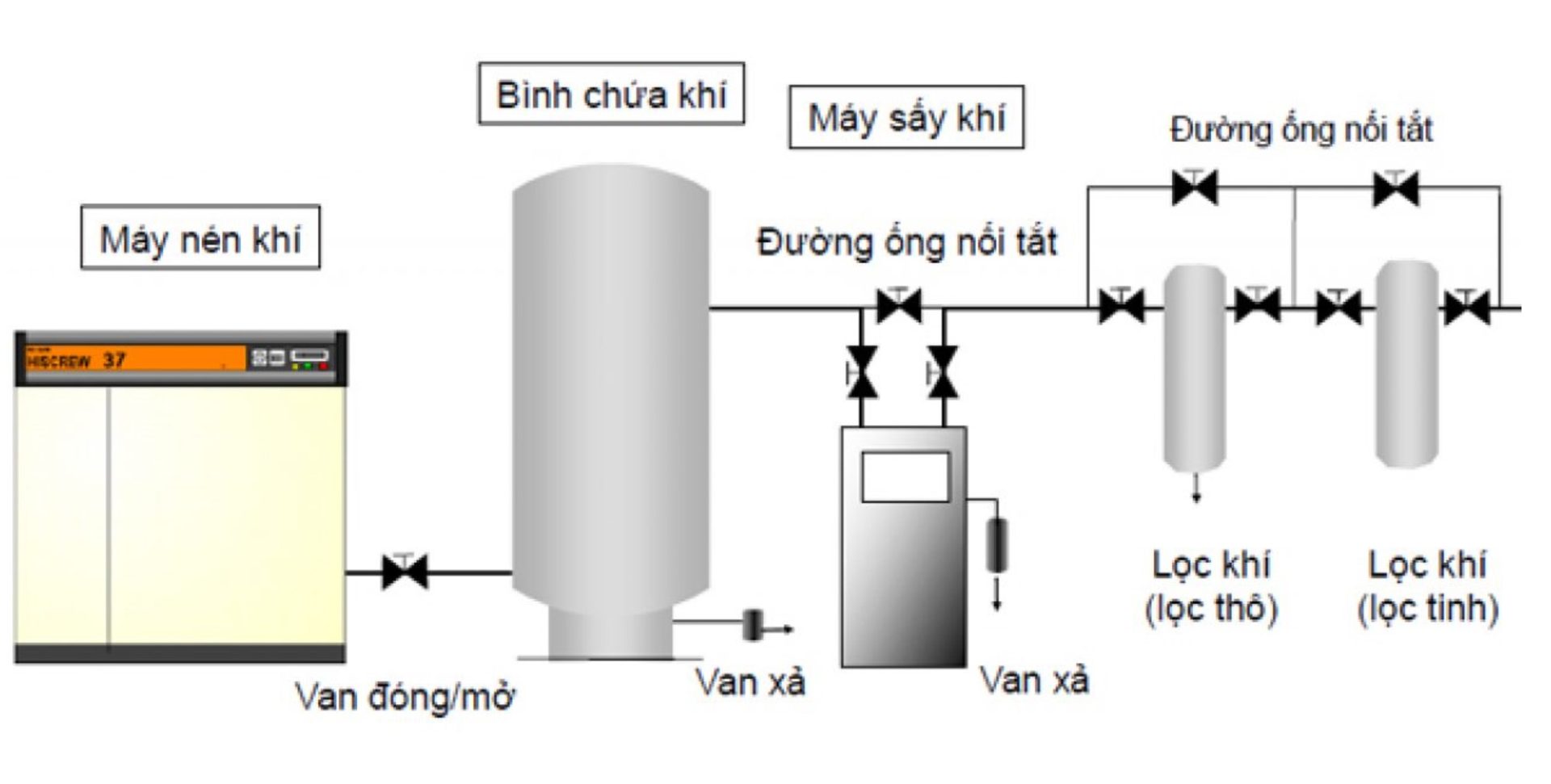

Compressed air tanks, also known as compressed air tanks, are an important device in the compressed air system, with the function of storing compressed air generated from the air compressor and providing stable compressed air to other equipment and machines in the system. It helps maintain stable pressure, prevent sudden pressure drops, and ensure the operation of compressed air equipment takes place continuously and effectively. In the compressed air system, the function of the compressed air tank is to store the amount of compressed air during the operation of machinery, engines and other components.

Compressed air tanks have an air compression mode that works under a pre-set pressure at the manufacturer’s specified level to maintain the pressure of the machine and provide compressed air flow to serve production and working needs.

Main functions of compressed air tanks:

Compressed air storage:

The compressed air tank acts as a storage tank, storing the amount of compressed air generated from the air compressor.

Stabilize pressure:

Help maintain stable compressed air pressure in the system, avoiding sudden pressure drops that affect the operation of compressed air equipment.

Continuous compressed air supply:

When equipment in the system needs to use compressed air, the tank will provide compressed air to meet the demand, ensuring that the production and working process takes place continuously and without interruption.

Separate water and cool compressed air:

During the process of compressing air, temperature and humidity can increase. The compressed air tank helps separate some of the water from the compressed air and cool the air before it enters the system.

Structure and operating principle:

Structure:

The compressed air tank is usually cylindrical, made of metal, hollow inside and can be lined with rubber to increase durability.

Operating principle:

The air compressor compresses air into the tank, when the pressure reaches the set level, the compressor will automatically turn off. When the system uses air, the air in the tank will be discharged, the pressure in the tank will decrease, the compressor will automatically turn on again to refill the tank.

Applications of compressed air tanks

Air tanks are devices used to stabilize the air pressure inside the tank, store air pumped from the air pump and use in many other cases. Therefore, there are many uses of compressed air tanks used in various economic activities of life.

– In daily life, compressed air tanks are used to store gas – providing gas for cooking and daily activities. The tank is also seen in welding activities, etc.

– In industrial production activities, compressed air tanks contain many essential gases in the production and combustion of metals and mechanical products.

– In the medical field, gas tanks are used to support the distillation of pure chemicals needed for medical and pharmaceutical work or are used in the process of treating liquid waste.

Manufacturing, mechanics:

Providing compressed air for equipment such as drills, cutters, paint sprayers, etc.

Food, pharmaceuticals:

Providing compressed air for production and packaging lines

Oil and gas, energy:

Used in oil and gas exploitation, transportation and processing activities

Construction, engineering:

Providing compressed air for equipment such as compactors, drills, concrete cutters

Medical:

Providing compressed air for medical equipment such as ventilators, anesthesia machines